mold or mould :

Mold is the American spelling for all senses of the word meaning, among other things,

(1) a frame for shaping something,

(2) to shape in a mold, and

(3) any of various fungi that commonly grow on organic matter and are often associated with decay.

Mould is the British spelling. American English has no mould, and British English has no mold.

Australian and Canadian English favour the British spelling, though mold is fairly common in Canadian publications.

The distinction extends to all derivative words, including molding (American) and moulding (British).

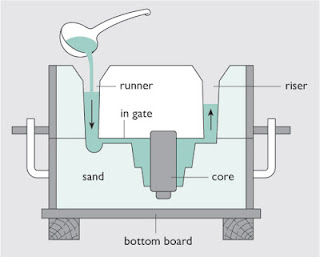

Casting

- Casting is a basic molding process as it requires the least amount of complex technology. Plastic is simply heated so it turns into a fluid, and then transferred into a mold. It is left to cool and the mold is removed. This process can be used for intricate shapes and performed under a low pressure. However, it is a common process used for making plastic sheeting, starting from 0.5 inches thick and greater.

Injection Molding

-

Injection molding is used for creating high-quality three-dimensional objects, that can be commercially reproduced. The molding process begins by melting plastic in a hopper. Then the plastic is injected into a tightly closed, chilled mold. The plastic quickly takes the shape of the surrounding mold. Once it has completely set, the mold is opened and the plastic object is released. Yogurt pots, butter tubs, toys and bottle caps are made using this process.

Blow Molding

-

Blow molding is a process used for making piping and milk bottles. Plastic is heated until molten. Then it is injected into a cold mold. The mold has a tube set within it, which has a particular shape when inflated. So, while the plastic is molten, air is blown into the tube and the plastic is formed around the tubing. It is then left to cool and removed from the mold.

Compression Molding

-

The most labor-intensive type of molding process is compression molding. Therefore, it is only used for large-scale production purposes, and not for mass production. For example, boat hulls and car tires are made using this method. Molten plastic is poured into a mold. Then a second mold is pressed into it. This squeezes the plastic into the desired shape before being left to cool and removed from the mold.

Rotational Molding

-

Toys, shipping drums, storage tanks and items of consumer furniture are made using rotational molding. Each object is made by coating a mold from the inside. A mold is held in place between two mechanical arms. Then, the arms rotate the mold constantly at the same level, while molten plastic is placed inside. As it turns, the plastic coats the inside of the mold to create a new hollow, plastic object.

Injection Molding:

http://www.bpf.co.uk/Data/Image/InjectionMoulding.swf

Injection molding has been one of the most important fabrication tools for the plastics industry since the reciprocating screw machine was patented in 1956. Today, it's almost impossible to do anything without using injection molded parts. They are used in automotive interior parts, electronic housings, housewares, medical equipment, compact discs, and even doghouses. Injection molding is used to fabricate pallets, toys, crates, and pails, thin-wall food containers, promotional drink cups, lids, and milk bottle caps.

The injection molding process involves melting the plastic in an extruder and using the extruder screw to inject the plastic into a mold, where it is cooled. Speed and consistency are vital keys to running a successful injection molding operation, since profit margins are normally below 10 percent.

Speed:

A molder will maximize output by minimizing cycle time which is the amount of time that is taken to melt the plastic, inject it into the mold, cool, and eject a finished part.

Using larger molds that produce more than one part each time the machine performs a cycle can also increase output. These molds are known as multiple cavity molds.

Consistency:

Consistency, or elimination of scrap and downtime, is just as important as output in a successful molding operation. The most consistent processing results from careful control of plastic temperature, plastic pressure as it fills the mold, the rate at which the plastic fills the mold, and the cooling conditions. These four primary molding variables are interdependent and can often be used to understand process changes and solve problems. While the variables apply to almost all injection molding processes, the process will be slightly different in each shop, depending on the application, the plastic being used, and the molder's preferences.

Fill rate:

In thin wall applications, the material must be injected into the mold as quickly as possible to prevent the plastic from freezing before the part has been completely filled. The newest resin and machine technologies in this area almost always focus on faster, easier fills. In addition to minimizing cycle time through better filling ability, the molder could realize resin cost savings through the ability to fill thinner molds or achieve higher outputs by using larger, higher cavity molds.

Thin wall molding is accomplished using machines that inject the material in less than one second and are big enough to support large, multiple cavity molds. Thin wall lids and containers tend to be small, so molds may be used to fabricate over 100 small lids at a time.

Defects in injection molding:

| Black Spots, Brown streaks:

Description

Black spots and brown streaks appear as dark spots or streaks in the

molded

part and are usually caused by thermal damage to the melt.

Possible Solutions

|

| Blisters (Air Entrapment):

Description

Blisters are hollows created on or in the molded part. In contrast to a

void

(vacuum) this entrapped gas can also appear near the walls.

Possible Solutions

|

| Brittleness:

Description

Brittleness is a condition where the part cracks or breaks at a much lower

stress level than would normally be expected based on the virgin material

properties.

Possible Solutions

|

| Bubbles:

Description

Bubbles are similar to blisters in that there is air entrapped in the

molded

part.

Possible Solutions

|

| Burn Marks, Dieseling:

Description

Burn Marks or Dieseling show up on the finish molded parts as charred or

dark

plastic caused by trapped gas and is usually accompanied by a distinctive

burnt

smell.Note: If this problem is allowed to continue without fixing the root cause it will very quickly cause damage to the molding surface.

Possible Solutions

|

| Cracking, Crazing:

Description

Cracking or Crazing is caused by high internal molded in stress or by an

external force imposed upon the part. They can also be caused by an

incompatible external chemical being applied to the finished parts The

cracks

often don't appear until days or weeks after the parts have been molded.

Possible Solutions

|

| Delamination:

Description

Delamination occurs when single surface layers start flaking off the

molded

part.

Possible Solutions

|

| Discoloration:

Description

Discoloration is similar to burn marks or brown streaks but generally not

as

dark or severe. It may cause the part to be a darker shade than the virgin

pellets and is often found nearest the gate area, however it can also

appear as dark streaks throughout the part.

Possible Solutions

|

| Excessive Flash:

Description

Excessive Flash is often seen near sealing faces, out of vent grooves, or

down

ejector pins. It appears as thin or sometimes thick sections of plastic

where

it would not be on a normal part.Note: Flash can very quickly (within a few cycles) damage the parting line surfaces.

Possible Solutions

|

| Flow, Halo, Blush Marks:

Description

Flow, Halo, Blush Marks are marks seen on the part due to flow of the

molten

plastic across the molding surface.Possible Solutions

|

| Gate Stringing, Drooling:

Description

The part does not break cleanly from the gate area.

Possible Solutions

|

| Gels:

Description

Gels are bubbles, or blisters seen on or in the part due to poor melt

quality.

Possible Solutions

|

| Jetting:

Description

Jetting is caused by an undeveloped frontal flow of melt in the cavity.

The

uninterrupted plastic flows or "snakes" into the cavity and cools off

enough so

that it does not fuse homogeneously with the material that follows.Possible Solutions

|

| Material Leakage:

Description

Material Leakage is usually caused by material forces overcoming the

structural

strength of the mold.NOTE: One sign that indicates that material has leaked is that the manifold reaches processing temperature very slowly.

Possible Solutions

|

| Oversized Part:

Description

Part is too large when compared to the drawing specifications.

Possible Solutions

|

| Part Sticking:

Description

Part is getting not pulling out of the cavity and in rarer circumstances

cannot

be ejected off the core.

Possible Solutions

|

| Short Shot (Incomplete Filled Parts):

Description

Short Shots occur when the part does not completely fill.

Possible Solutions:

|

| Sink Marks:

Description

Sink Marks occur during the cooling process if certain areas of the part

are

not cooled sufficiently causing them to contract.Possible Solutions:

|

| Splay Marks, Silver Streaks:

Description

Splay Marks, Silver Streaks are usually caused by water vapor blisters at

the

flow front burst and freeze on the wall of the molding surface.

Possible Solutions:

|

| Sprue Sticking:

Description

Sprue Sticking generally occurs in a cold runner mold when the sprue is

staying

in the mold.

Possible Solutions:

|

| Surface Finish (Low Gloss):

Description

Surface Finish (Low Gloss). Gloss is the appearance of the surface of the

molded part when light is reflected off of it. Molds that are textured or

resins that are filled have an inherently reduced level of gloss when

compared

to highly polished mold surfaces.

Possible Solutions:

|

| Surface Finish (Scars, Wrinkles): Description Surface Finish (Scars, Wrinkles). Is the appearance of the ripples or wrinkles on the surface of the molded part. Possible Solutions:

|

| Undersized Part:

Description

Part is too small when compared to the drawing specifications.

Possible Solutions:

|

| Valve Pin Does Not Close:

Description

Valve pin does not close properly. This will leave the gate protruding

from the

part. This may also occur if the valve pin is too hot, the material may

stick

to the valve pin.

Possible Solutions:

|

| Voids:

Description

Voids are hollows created in the part. They are normally found in thick

sectioned parts caused by material being pulled away from the hot center

section towards cold mold walls leaving a void in the center.Possible Solutions:

|

| Warping, Part Distortion:

Description

Warping, Part Distortion is shows up as parts being bowed, warped, bent or

twisted beyond the normal specification outlined on the drawing.

Possible Solutions:

|

| Weld Lines:

Description

Weld Lines are created when two or more melt flow fronts meet possibly

causing

a cosmetically visible line. It can also create a weakened area in the

finished

molded part especially with filled resins.

Possible Solutions:

|

SINO PACKAGE MOULD CO. is a leading Chinese Plastic Bottle Cap Molds Maker juice cap mould with 48 cavities, 64 cavities and 96 cavities cap mould.

ReplyDeletePlastic bottle cap moulds

I have enjoyed reading your articles. It is well written. It looks like you spend a large amount of time and effort in writing the blog. I am appreciating your effort. You can visit my website.

ReplyDeleteblow molding machine

I found Great collections of information from your post. I will give credit to you for this. Mold and Mould are same. Only difference is in language i.e. American and British. I completely agree with Mr. Tasnim that you spend a large amount of time and effort in writing this blog.Thanks and keep posting such articles.

ReplyDeleteCustom Mould

hi friends .. thank you for the comments

ReplyDeleteMould is main part of injection moulding process. I am employee at hangplas in UK and our experienced employee take care the all process and also provide best quality of the production to the customers.

ReplyDeleteWell written post. I like to read something on Injection Molding Process its include all process with Description.very intresting and important post for me. Thanks for sharing.

ReplyDeletePlastic Injection Moulding Machine

This article is very informative and provided lots of facts about plastic injection moulding

ReplyDeleteNice Post Anbuvelavan. you explained very clearly about Injection Molding process.

ReplyDeleteThanks for the post.

BuildProtos

ReplyDeleteThanks for sharing this much valuable content with us, if you are looking for injection moulds, we are here for you. we are the best Plastic injection moulding machine manufacturers in india. thanks again for this blog post.

This comment has been removed by the author.

ReplyDeleteinjection mold china Your blog is very good. I have got a lot of sari information from this and it was very nice to me.

ReplyDeleteWe are Top Most Plastic Cap Mould Manufacturers In India. Click here for more details.

ReplyDeleteVery informative and impressive post you have written, this is quite interesting and i have went through it completely, an upgraded information is shared, keep sharing such valuable information. Plastic Injection Molding

ReplyDeleteinjection moldLooking for A plastic injection mold China company? We offer the best quality plastic mold, injection mold, your best, plastic injection molding China supplier.

ReplyDeleteWe are a professional plastic mold maker in China with a high quality of plastic injection molding. Choose Chinese mold and services to increase your business. Visit us.

ReplyDeleteFor More Information Visit Here -- china mold maker

Your post is really good. Useful content. Very helpful to me. i have similar products.see my products also...

ReplyDeleteinjection molding cost

thank you sir your post is very good i am working injection molding machine it is very helpful for me thank you very much

ReplyDeletemechanical

can you explain me booster time used many time in this article

ReplyDeleteplastic injection moulders

ReplyDeleteLooking for A plastic injection mold China company? We offer the best quality plastic mold, injection mold, your best, plastic injection molding China supplier.

Well....I have no words for this awesome post!!!

ReplyDeletePlastic Mold Company

Hi Dear

ReplyDeleteI have read your post and it's very interesting post. I have achieved valuable thoughts from your post. Thanks for sharing such great post...

injection molding china Find the best custom plastic injection molding manufacturers and companies at injectionmoldmfg.com

If you would like more information, Visit Site

Injection mold china

ReplyDeleteAluminum Casting China company is offering good quality aluminum die casting, aluminum casting parts, aluminium die casting,if you need die casting china?

Injection molding china

ReplyDeleteIf you are looking for plastic injection molding companies you are in the right place. We provide double injection mold to companies in China.

Nylon cable High Speed Machine

ReplyDeleteDo you need automatic Nylon cable High-Speed Machine to use touch screen digital adjustment and expand the production of output units? If yes, then welcome to Global Plastech is offering top-notch machines.

Thanks for this blog post admin, you have done really nice work.

ReplyDeleteChina Plastic Mold Company

Impressive.. I loved this post.

ReplyDeletechina plastic injection molding

plastic injection molding china

plastic injection moldingmanufacturer

Double injection molding - We offer custom injection mold and molding, including double injection molding, over-molding, 2 color molding, need any double injection molding. Contact us - +86-0769 33857766". For More Information Visit Here -- double injection molding

ReplyDeleteBest plastic injection mold components. We can manufacture the injection mold per your requests with competitive prices. For more information about plastic injection mold visit here". For More Information Visit Here -- plastic injection mold components

ReplyDeleteThis article is one of a kind, so helpful.

ReplyDeleteInjection molding China

injection mold company

injection mold maker

Hi there I am so thrilled I found your website, I really found you by mistake, while I was browsing on Yahoo for something else Mold Manufacturers In China

ReplyDeleteI am a regular reader of your blog, Amazing content with proper examples. Thank you admin. Plastic Molding Manufacturing

ReplyDeleteHalo,I'm Helena Julio from Ecuador,I want to talk good about Le_Meridian Funding Service on this topic.Le_Meridian Funding Service gives me financial support when all bank in my city turned down my request to grant me a loan of 500,000.00 USD, I tried all i could to get a loan from my banks here in Ecuador but they all turned me down because my credit was low but with god grace I came to know about Le_Meridian so I decided to give a try to apply for the loan. with God willing they grant me loan of 500,000.00 USD the loan request that my banks here in Ecuador has turned me down for, it was really awesome doing business with them and my business is going well now. Here is Le_Meridian Funding Investment Email/WhatsApp Contact if you wish to apply loan from them.Email:lfdsloans@lemeridianfds.com / lfdsloans@outlook.comWhatsApp Contact:+1-989-394-3740.

ReplyDeleteThanks for sharing this kind of information with us.

ReplyDeleteHigh Quality Injection Molding

Excellent post. Thank you for sharing.

ReplyDeleteChina Plastic Injection Molding Manufacturer

Hi, really appreciate you for this awesome article you have covered all the pin points of the topic in this article keep up the good work. Cheers! Screen Printing Machine for Plastic Bottles

ReplyDeleteNUBS Plastics Inc is the Best Injection Molding Company.

ReplyDeleteExperience to provide unparalleled all-around custom plastic design Service in Auburn, CA. Whatever your product is, we possess the knowledge and know-how to

ReplyDeletePlastic Injection Molding Service Auburn

very good article, I have found this documentation that may interest you about Capacities and Sizes of Plastic Injection Moulding Machines

ReplyDelete

ReplyDeleteBasically, injection molding is one among the foremost common manufacturing processes.

China Custom Plastic Injection Molding Maker

Injection molder When your website or blog goes live for the first time, it is exciting. That is until you realize no one but you and your.

ReplyDeleteAs a result, it is essential to monitor the temperature of the molding rig to avoid overheating or underheating the plastic. You are curious to know more about rotomolding, discover here.

ReplyDeleteThanks for sharing great content with all of us. You have shared really unique and useful content with us, I really appreciate it. Custom Molding Services

ReplyDeleteHEAVY QUALITY PRODUCT :

ReplyDeleteCNC milling

Parting line injection molding

Stamping punch

Guide bushing

Stamping die

We have a specialized team for your Access control system installation, Front gate Repair, Gate opener install, and Gate Motor installer in Auburn. Call now - (800) 881-8570

ReplyDeleteVisit here : Automatic Gate Repair in Auburn

Admin, thank you for this great post. You've done an excellent job. Thank you, and please keep up the good work. Consider reading about the Best Injection Molding Company with Manufacturers' Quality if you are interested in technology and business. Thank you once more.

ReplyDeleteThank you for your wonderful article, admin. You've performed admirably. Thank you for your time and thought, and please continue to do such a fantastic job. If you want to learn more about the top Injection Molding Manufacturers with great quality. If you're interested in technology and business. Thank you once again.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteto everyone. Keep sharing this kind of articles, insert injection molding mold

ReplyDeleteSmart moulding product's :

ReplyDeleteMoulding components |

Insert molding |

CNC milling |

Mould cavity |

Parts of injection |

Insert molding |

ReplyDeleteHeavy quality product's :

CNC milling |

Mould cavity |

Parts of injection |

Insert molding |

I read your post and found really interesting things about Injection Molding Manufacturers plastic products. Your post has given me some useful ideas. Thank you for sharing such an informative article.

ReplyDeleteThis comment has been removed by the author.

ReplyDeleteThanks for sharing this informative post on the Best Injection Molding Company. It's great to learn more about the key capabilities and services they offer. Their expertise in complex part design and high-precision manufacturing seems really impressive.

ReplyDelete