Automatic Air Suspension

Suspension is the term given to the system of springs , shock

absorbers and linkages that connects a vehicle to its wheels .

Suspension systems serve a dual purpose — contributing to the car's road

holding handling and braking for good active safety and driving

pleasure, and keeping vehicle occupants comfortable and reasonably well

isolated from road noise, bumps, and vibrations, etc. These goals are

generally at odds, so the tuning of suspensions involves finding the

right compromise. It is important for the suspension to keep the road

wheel in contact with the road surface as much as possible, because all

the forces acting on the vehicle do so through the contact patches of

the tires. The suspension also protects the vehicle itself and any cargo

or luggage from damage and wear. The design of front and rear

suspension of a car may be different.

There are two types of suspension systems- dependent and independent. A dependent suspension comprises a beam that holds wheels parallel to each other and perpendicular to the axle. An independent suspension helps in the rising and falling movement of the wheels. There is also a semi-dependent suspension where the motion of one wheel affects the position of the other but they are not rigidly attached to each other.

The dependent suspension includes Trailing arms, Satchell link, Panhard rod, Watt's linkage, WOBLink and Mumford linkage. The independent suspensions includes Swing axle, Sliding pillar, MacPherson strut/Chapman strut, Upper and lower A-arm (double wishbone), multi-link suspension, semi-trailing arm suspension, swinging arm and leaf springs.

Air Spring:

Air springs combine spring and shock absorbing action in one unit and were often used without metal springs. The first one was developed by Cowey Motor Works of Great Britain in 1909. It was a cylinder that could be filled with air from a bicycle pump through a valve in the upper part of the housing. The lower half of the cylinder contained a diaphragm made of rubber and cord which, because it was surrounded by air, acted like a pneumatic tire. Its main problem was that it often lost air.

The newest air spring, developed by Goodyear, is found on some late-model Lincolns. Like the ones that have preceded them, these ride-on-air units are more costly than conventional springs and hydraulic shock absorbers.

The air suspension system is an air-operated, microprocessor controlled suspension system. This system replaces the conventional coil spring suspension and provides automatic front and rear load leveling. The 4 air springs, made of rubber and plastic, support the vehicle load at the front and rear wheels'.

An air suspension supports the vehicle on the axles with an arrangement of air bags instead of some type of steel spring, leaf or coil, or some type of torsion spring arrangement. The air bags are sometimes referred to as air springs or bellows. Suspensions that have steel or torsion springs that are supplemented by the use of air bags are not considered air suspensions. There are combination systems that have both air and steel springs. Usually the air suspension components are used on the rear of the vehicle.

Advantages of air suspenson system :

—Excellent Suspension & Comfort to passengers

Fully Automatic Level Control

—Good handling

—Shields the vehicle from damage

—Keeps the tires pressed firmly to ground

—Easy To Service

—Lifting & Lowering Function

—Increases life of vehicle

Air ride

suspension carries the load on each axle with a pressurized air bag much

like a high pressure balloon. Air ride suspension systems have been in

common use for over forty years and have proven to provide the smoothest

and most shock-free ride of any known vehicle suspension system. Modern

air bags are constructed using the same methods as a tire by using high

strength cords which are then encapsulated in rubber. These units are

very durable in service and have a proven life of many years.

In addition to providing extremely smooth ride quality, air ride suspension also provides other important features. First, the system automatically adjusts air pressure in the air bag so that the trailer always rides at the same height, whether lightly loaded or heavily loaded. This allows the suspension system to always provide the maximum usable wheel travel independent of trailer load. In addition, the higher air bag pressure associated with higher trailer loads, automatically provides a stiffer suspension which is exactly what is required for a smooth ride. The lower air bag pressure for lightly loaded conditions, automatically provides for a softer suspension, thus providing the same ride quality for all trailer loading conditions. Since each axle is independently supported by its own air bag, the air ride suspension is a truly, fully independent suspension system.

The automatic control of the air bag pressure is accomplished by a solid state electronic control system specifically designed and packaged for vehicle use. This system continuously monitors the "ride height" of the trailer suspension and increases air pressure if the ride height is too low, by turning on an on-board air compressor. The air compressor stops automatically when the proper ride height is reached. If the ride height is too high, an automatic vent valve vents excess air pressure and stops venting when the proper ride height is reached. All required electrical power is provided by a 12 volt battery contained in the trailer equipment compartment

In addition to providing extremely smooth ride quality, air ride suspension also provides other important features. First, the system automatically adjusts air pressure in the air bag so that the trailer always rides at the same height, whether lightly loaded or heavily loaded. This allows the suspension system to always provide the maximum usable wheel travel independent of trailer load. In addition, the higher air bag pressure associated with higher trailer loads, automatically provides a stiffer suspension which is exactly what is required for a smooth ride. The lower air bag pressure for lightly loaded conditions, automatically provides for a softer suspension, thus providing the same ride quality for all trailer loading conditions. Since each axle is independently supported by its own air bag, the air ride suspension is a truly, fully independent suspension system.

The automatic control of the air bag pressure is accomplished by a solid state electronic control system specifically designed and packaged for vehicle use. This system continuously monitors the "ride height" of the trailer suspension and increases air pressure if the ride height is too low, by turning on an on-board air compressor. The air compressor stops automatically when the proper ride height is reached. If the ride height is too high, an automatic vent valve vents excess air pressure and stops venting when the proper ride height is reached. All required electrical power is provided by a 12 volt battery contained in the trailer equipment compartment

Introduction of Suspension system:

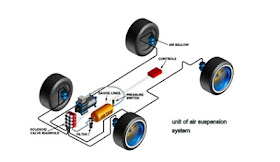

Figure 1: Locating Suspension Units

A suspension system comprises springs, shock

absorbers and linkages. This suspension connects an automobile to its

wheels. The suspension systems not only help in the proper functioning

of the car's handling and braking, but also keep vehicle occupants

comfortable and make your drive smooth and pleasant. It also protects

the vehicle from wear and tear. To know about the suspension system, one

needs to know about the spring rate or suspension rate. Various spring

types are used for different vehicles. In case of heavier suspension

loads, the spring rate is higher and vice versa. Spring rate is measured

as a ratio used to measure how resistant a spring is to being

compressed or expanded during the spring's deflection Besides spring

rate, one needs to take in account the wheel rate. Wheel rate is the

effective spring rate when measured at the wheel. It is generally equal

to or considerably less than the spring rate.There are two types of suspension systems- dependent and independent. A dependent suspension comprises a beam that holds wheels parallel to each other and perpendicular to the axle. An independent suspension helps in the rising and falling movement of the wheels. There is also a semi-dependent suspension where the motion of one wheel affects the position of the other but they are not rigidly attached to each other.

The dependent suspension includes Trailing arms, Satchell link, Panhard rod, Watt's linkage, WOBLink and Mumford linkage. The independent suspensions includes Swing axle, Sliding pillar, MacPherson strut/Chapman strut, Upper and lower A-arm (double wishbone), multi-link suspension, semi-trailing arm suspension, swinging arm and leaf springs.

Air Spring:

Air springs combine spring and shock absorbing action in one unit and were often used without metal springs. The first one was developed by Cowey Motor Works of Great Britain in 1909. It was a cylinder that could be filled with air from a bicycle pump through a valve in the upper part of the housing. The lower half of the cylinder contained a diaphragm made of rubber and cord which, because it was surrounded by air, acted like a pneumatic tire. Its main problem was that it often lost air.

The newest air spring, developed by Goodyear, is found on some late-model Lincolns. Like the ones that have preceded them, these ride-on-air units are more costly than conventional springs and hydraulic shock absorbers.

The air suspension system is an air-operated, microprocessor controlled suspension system. This system replaces the conventional coil spring suspension and provides automatic front and rear load leveling. The 4 air springs, made of rubber and plastic, support the vehicle load at the front and rear wheels'.

An air suspension supports the vehicle on the axles with an arrangement of air bags instead of some type of steel spring, leaf or coil, or some type of torsion spring arrangement. The air bags are sometimes referred to as air springs or bellows. Suspensions that have steel or torsion springs that are supplemented by the use of air bags are not considered air suspensions. There are combination systems that have both air and steel springs. Usually the air suspension components are used on the rear of the vehicle.

Figure 2: Advanced Air Suspension

Depending on the situation, this type of air suspension will

probably have to be dealt with for leveling purposes. Normally, the air

suspension is just one part of the air system on the vehicle. Most (but

not all) vehicle with an air suspension also have air brakes along with

other equipment that may be operated with air. Any of these other

systems can cause problems with the air suspension. Other air systems

including the brake systems in general, will not be discussed in this

school. It is important to understand that on vehicles with air systems,

especially with air brakes, manufacturers must follow specific

regulations when designing their air systems. The brake system will

always be the main concern for the air system. There will be safety

features installed in the system that make the brake system the main

priority for the air system.Advantages of air suspenson system :

—Excellent Suspension & Comfort to passengers

Fully Automatic Level Control

—Good handling

—Shields the vehicle from damage

—Keeps the tires pressed firmly to ground

—Easy To Service

—Lifting & Lowering Function

—Increases life of vehicle

—

Wonderful blog & good post.Its really helpful for me, awaiting for more new post. Keep Blogging!

ReplyDeleteTorsion springs

thank you ajatshatru

Delete

ReplyDeleteMany Autos repair and replace ABS sensor, ABS pump,ABS ring for all makes and models in Reading, United Kingdom. We also provide free collection and Delivery service from your home or place of work.

to everyone. Keep sharing this kind of articles, mold secondary processing

ReplyDelete